Post by : Zayd Kamal

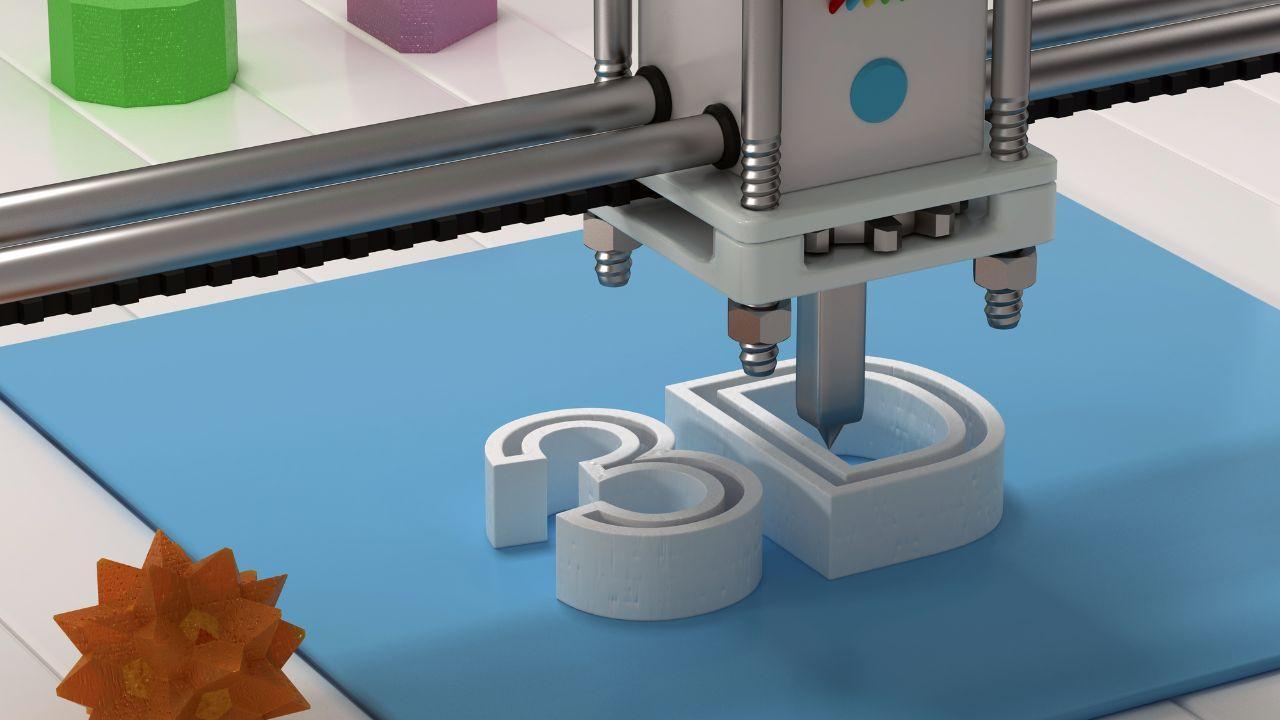

The world of manufacturing and design is undergoing a revolutionary transformation thanks to the advent of 3D printing technology. This innovative process, also known as additive manufacturing, has rapidly evolved, making it possible to create complex designs and functional prototypes with unparalleled precision and efficiency. In this article, we’ll explore how 3D printing is changing manufacturing and design, revolutionizing industries and reshaping the future of production.

3D printing is a process that builds objects layer by layer using materials such as plastics, metals, ceramics, and even biological substances. Unlike traditional manufacturing methods that involve cutting or molding, 3D printing allows for the creation of intricate shapes and structures with minimal waste. This technology is used across various industries, from aerospace and healthcare to fashion and architecture.

One of the most significant impacts of 3D printing in manufacturing is the ability to create prototypes quickly. In traditional manufacturing, developing a prototype could take weeks or even months. With 3D printing, designers can produce a prototype in a matter of hours or days, enabling rapid iterations and innovation.

For example, car manufacturers are using 3D printing to test new designs and improve vehicle performance. This agility helps companies stay ahead of the competition and bring innovative products to market faster.

3D printing technology has made it easier than ever to produce customized products. In industries such as healthcare, this has been a game-changer. From patient-specific implants and prosthetics to customized surgical tools, 3D printing in design allows for a level of personalization that was previously unimaginable.

Similarly, the fashion and jewelry industries are embracing 3D printing to create bespoke designs tailored to individual customers. This customization enhances user satisfaction and opens up new opportunities for creativity.

Sustainability is becoming a crucial consideration in modern manufacturing. Traditional production methods often result in significant material waste. In contrast, 3D printing is inherently efficient, using only the necessary amount of material to create an object.

Additionally, many companies are experimenting with recyclable and biodegradable materials for 3D printing, further reducing the environmental impact. By minimizing waste and optimizing resource use, 3D printing in manufacturing contributes to a more sustainable future.

In traditional manufacturing, creating complex designs often requires intricate molds and tooling, which can be time-consuming and expensive. 3D printing technology removes these barriers, allowing manufacturers to produce complex shapes and intricate patterns with ease.

For instance, the aerospace industry uses 3D printing to create lightweight yet strong components for aircraft and spacecraft. These advanced designs improve efficiency and reduce costs, highlighting the transformative potential of 3D printing in design.

While the initial setup for 3D printing can be costly, the long-term savings are substantial. Traditional manufacturing requires significant investment in machinery, molds, and labor. In contrast, 3D printing in manufacturing reduces costs by eliminating the need for expensive tooling and minimizing material waste.

Moreover, as 3D printing technology becomes more accessible, small businesses and startups are leveraging it to compete with larger companies. Entrepreneurs can now turn their ideas into reality without needing massive production facilities.

The decentralized nature of 3D printing is transforming global supply chains. Manufacturers can produce parts and products locally, reducing shipping costs and lead times. This shift is particularly valuable in industries where quick response times are critical, such as healthcare and aerospace.

By enabling on-demand production, 3D printing also helps companies maintain smaller inventories, reducing storage costs and minimizing the risk of overproduction.

As 3D printing technology continues to advance, its applications will only expand. Innovations like multi-material printing, bioprinting for medical purposes, and larger-scale printers promise to push the boundaries of what is possible.

From reshaping supply chains to enabling breakthroughs in personalized medicine, 3D printing is poised to play a central role in the future of manufacturing and design. As industries adapt to this technology, the opportunities for innovation and efficiency will continue to grow.

The article explores how 3D printing technology is revolutionizing manufacturing and design, transforming industries with faster prototyping, enhanced customization, and sustainable production. It highlights the advantages of 3D printing, including reduced waste, cost efficiency, and the ability to create complex designs with ease. Industries like healthcare, aerospace, and fashion are leveraging this innovative technology to push boundaries and foster creativity. The article also discusses how 3D printing is reshaping supply chains by enabling localized, on-demand production, paving the way for a sustainable and efficient future.

This article is published by DXB News Network for informational purposes only. While we strive to ensure accuracy, the content reflects general trends and insights about 3D printing technology and may not cover all specific developments or applications. For detailed advice or professional insights, readers are encouraged to consult industry experts or reliable sources.

Predictheon Wins WHX Xcelerate Innovation Champion 2026

Predictheon won WHX 2026 Xcelerate, earning US$12,000, WHX 2027 space and global exposure for its AI

Omantel Launches Otech to Drive Oman’s Future Tech Vision

Omantel launches Otech to accelerate Oman’s digital transformation, strengthen data sovereignty, exp

Daimler Truck MEA Honors Top Distributors at EliteClass 2025

Daimler Truck MEA hosted EliteClass Awards 2025 in Dubai, honoring top distributors across 19 catego

King Mohammed VI Launches Safran Landing Gear Plant in Morocco

Morocco strengthens its aerospace leadership as King Mohammed VI launches Safran’s €280M landing gea

Qatar Emir Sheikh Tamim Arrives in UAE on Fraternal Visit

Qatar’s Emir Sheikh Tamim bin Hamad Al Thani arrived in Abu Dhabi on Saturday. UAE President Sheikh

Shaidorov Wins Stunning Olympic Gold as Malinin Falters

Kazakhstan’s Mikhail Shaidorov won men’s figure skating gold after US star Ilia Malinin fell twice.

Shakira’s 5-Show El Salvador Residency Boosts Bukele Image

Shakira’s five sold-out concerts in San Salvador highlight El Salvador’s security shift under Bukele

Why Drinking Soaked Chia Seeds Water With Lemon and Honey Before Breakfast Matters

Drinking soaked chia seeds water with lemon and honey before breakfast may support digestion hydrati

Morning Walk vs Evening Walk: Which Helps You Lose More Weight?

Morning or evening walk Learn how both help with weight loss and which walking time suits your body

What Really Happens When You Drink Lemon Turmeric Water Daily

Discover what happens to your body when you drink lemon turmeric water daily including digestion imm

DXB News Network Presents “Ctrl+Alt+Wim”, A Bold New Satirical Series Starring Global Entertainer Wim Hoste

DXB News Network premieres Ctrl+Alt+Wim, a bold new satirical micro‑series starring global entertain

High Heart Rate? 10 Common Causes and 10 Natural Ways to Lower It

Learn why heart rate rises and how to lower it naturally with simple habits healthy food calm routin

10 Simple Natural Remedies That Bring Out Your Skin’s Natural Glow

Discover simple natural remedies for glowing skin Easy daily habits clean care and healthy living ti

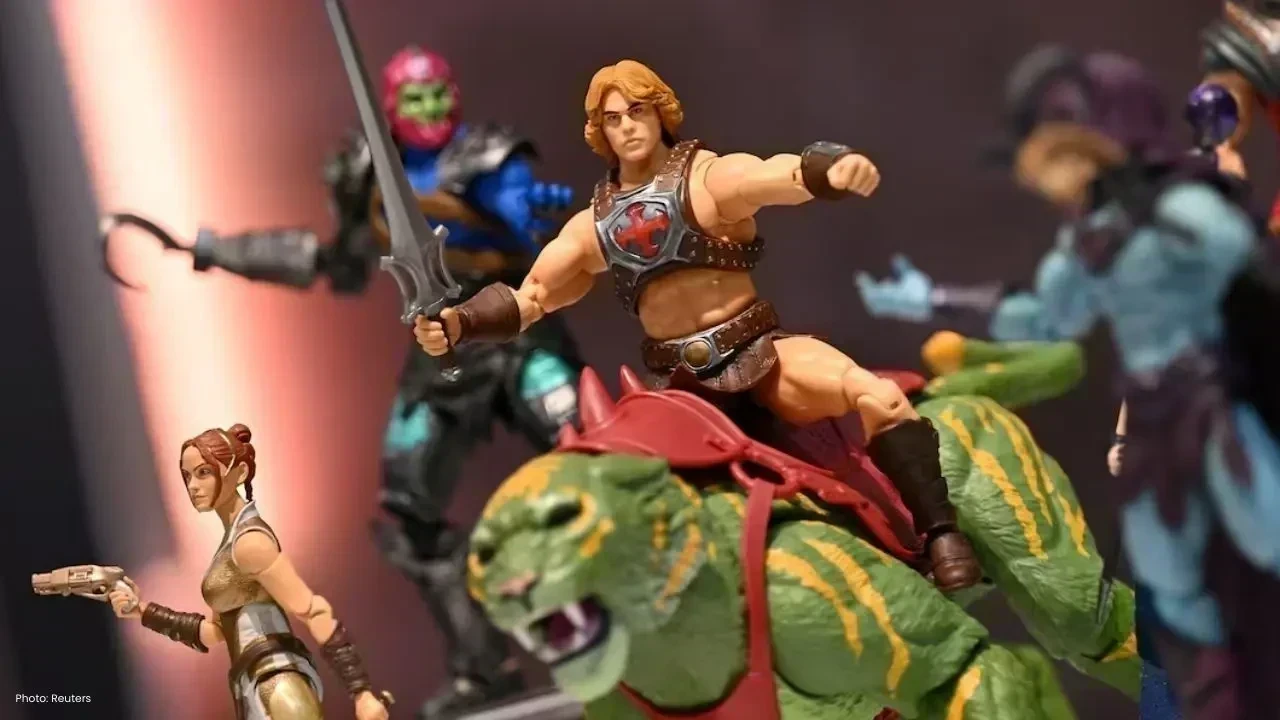

Mattel Revamps Masters of the Universe Action Figures for Upcoming Film

Mattel is set to revive Masters of the Universe action figures in sync with their new movie, ignitin

China Executes 11 Members of Infamous Ming Family Behind Myanmar Scam Operations

China has executed 11 Ming family members, linked to extensive scams and gambling in Myanmar, causin